Portfolio

We were approached by a national security company to help develop some training aids.

The current method for educating personnel was to have mechanical cut away parts that could be passed round and studied (hands on) with a question and answer session. This was proving time consuming and ineffective.

Wilson Design created detailed 3D models and exploded assemblies plus video clips that could all be embedded in to a PowerPoint presentation for easy distribution, saving time and money.

A local electronics engineer was building a scale model of a Mosquito fighter plane, he approached Wilson Design to help with modelling the front wheel that would work exactly the same as the original. It needed to retract up into the body in a tight space and lock down on landing with impact springs for shock absorbance. It would also accommodate the small electric motor and limit switches.

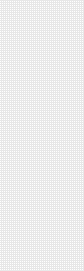

Whilst working for IGUS® (www.igus.co.uk) a manufacturer of high class riffle butts asked us to look at how we could improve a mechanism they used for extending and retracting chin and arm rests. We took the idea and added IGUS® bearings and shafts to create a very cost effective solution, now supplied as a kit.

We were asked by a local Royal Enfield Distributor Cooperb Motorcycles (https://www.cooperbmotorcycles.co.uk) to design and manufacture some after market sheet metal parts for various models, including stainless steel Chain Guards for the Continental GT and Bash plates for the brand new Himalayan off road style bike.

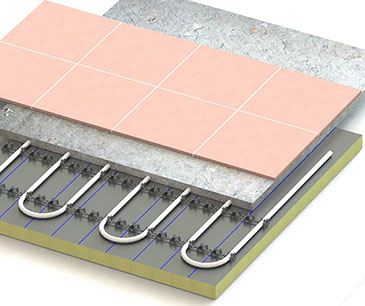

Whilst contracted to Hartridge (http://www.hartridge.com) a world leader in diesel fuel injection testing technology. Wilson Design developed and tested a now patented Cambox. Its unique features allow the operator to quickly and effectively change cam position altering the lift required to test any EUI and EUP diesel injector.

Wilson Design have been contracted to assist with local design applications for IGUS (www.igus.co.uk) a worldwide manufacturer and distributor of plastic plain bearings, spherical bearings, linear guides, cable carriers and continuous-flex cables. We take simple sketches and photographs and turn them into working models for customer approval.

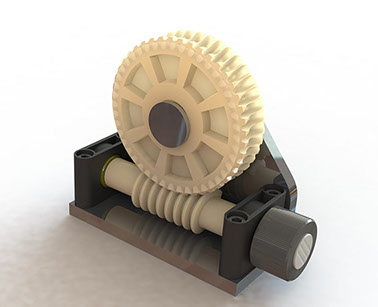

Base UFH a supplier of bespoke underfloor heating systems they approached Wilson design to create some high quality images for use on a website. They need to show a cross section of each type of system in a realistic way.

Whilst contracted to Earlsdon Technology we designed a hydraulic bearing jig for use on a Mazak CNC machine. The jig was for final machining of car engine main bearings.

Xtracs a supplier of display stands and barriers asked us to create some nice rendered images for brochures and catalogues. We came in on time and on budget.

x

Wilson Design Technology, your number 1 manufacturing designer and mechanical design engineer.

Website Created by: KG Graphic Design

Copyright© Wilson Design Technology 2018